‘Best Model Plantation’ fires hope: Quest to turn Sabah into a key wood producer again

Published on: Sunday, March 10, 2024

By: Kan Yaw Chong

Text Size:

Canopy of planted Albizia.

TURNING Sabah back to a key timber producer again is a top State government aspiration.

The secret is probably vesting the hundreds of thousands of hectares of Sabah’s degraded forest in the hands of the right people who perform. The State government should believe it can achieve this goal that thrives on an oasis of functioning forest plantations that deliver superior timber outputs.

In this Part 2 of a series, this is precisely our highlight – that Jawala Plantation Industries Sdn Bhd which, won the “Best Model Forest Plantation” award in June 2023, had conclusively demonstrated it was able to produce an output of wood from planted trees seven times larger than that of salvaged tropical logs from the same degraded forests.

The trial harvest of one hectare of Albizia: Wood output – 210c3/ha.

Given this good story or good news expounded here, the Sabah government which had identified 400,000ha of degraded forests under its 2022-2036 Forest Plantation Development Action Plan, has every right to an optimism that it shall be accomplished, and enjoy the expected revenues of up to RM30 billion per year in 10 years.

Empowering numbers from Jawala Plantation

Here, we look at some empowering numbers from Jawala’s forest plantation’s trees planted on a degraded forest in Sapulut, said to have yielded a commercial wood output seven times higher than the tropical logs salvaged from the same degraded forest.

That gladdening number centers on per ha Alzizia planted only five years ago in 2018, it yielded 210c3 of wood and 135c3 timber per ha Laran, in a trial harvest in October 2023 and milled in Tawau – far higher than just 30c3 per ha of salvaged tropical logs from degraded forests.

Rahman

Rahman cited repeatedly hailed these encouraging statistics on superior timber output from planed trees on degraded forests will lead to greater conservancy, sustainability and renewability of Sabah’s forest resources.

Excited by this positive outcome, Group CEO of Jawala Inc and subsidiary, Jawala Plantation Industries CEO, Rahman Khan, argued that Sabah can do the same and has the potential make a major economic success out of the 1.2m ha FMU, especially its vowed objective to green the 400,000ha of degraded forests under its 2023-36 Forest Plantation Development Plan.

Principal source of timber from genuine efforts

Rahman is not alone on the prospect of forest plantation breakthrough.

State forestry officials had conclusively established that tree plantations will have to be the principal source of timber in Sabah in the future, as the long term sustainability of timber production in Sabah had been a matter of great concern over the recent decades.

Beautiful logs from a trial harvest of one hectare of Laran: Wood output – 135c3/ha.

Dr Robert Ong, Director of Forest Research Centre of Sabah Forestry Department, concluded that in a co-authored paper entitled “25-year Projection of Timber Production for Sabah”, where he saw neither selective logging from natural forests nor salvage logging from degraded forests, are significant any more.

So this Special Report is intended to raise eyebrows that Jawala Forest Plantation shows that when the chips are down, genuine and serious efforts can cause degraded forests to produce prolific commercial wood output from planted logs seven times more than the vaunted tropical logs.

The golden narrative

Looking at this number, Rahman grasped a golden narrative he said no FMU king pins had seized to articulate to the general public actually one hectare of forest plantation developed on already degraded forest can spare 7ha of tropical forests from destruction.

Success in articulating this positive narrative would have spared FMU’s from bad public opinions running in this vein – oh, they are cutting the forests, when in fact, they are planting commercial logs to spare what remains of the natural forests from being destroyed.

Since Sabah has 26 Sustainable Forest Management Licence holders of which Pawala Forest Plantation Industries is the youngest and smallest, most of them have the advantage of the economy of scale that Rahman says Jawala does not have.

State policy: Plant on degraded forests only

“By virtue of State policy, forest plantations are allowed to plant only in degraded forests within their concessions, where timber stands are poor, our business model is we clear that, we sell whatever salvage logs from that, then we invest in the planting. So FMUs can do the natural forests and timber trade a favour big time,” Rahman noted.

“Here are some quick numbers, the degraded forests we had in our concession produce about 30 cubic metres of commercial timber stands per hectare. Generally this is true all over Sabah, but in a matter of five to eight years, our forest plantations developed on the same degraded forests turned out to be seven times more productive!” Rahman noted.

The purpose of it all-save the natural forests

“Specifically, a trial harvest of one hectare of Alzizia yielded 210c3 metres of wood and one hectare of Laran, both planted in 2018, yielded 135c3 when sent to a Tawau mill for processing in Oct 2023, far exceeding just 30m3 from salvaged logs extracted from the degraded forests earmarked for planting.

“So I am pleased to tell everybody what this means is that for every hectare of forest plantation I develop, it translates into saving seven hectares of tropical forests, leading to greater conservancy, sustainability and renewability of Sabah’s forest resources,” Rahman kept hitting it home.

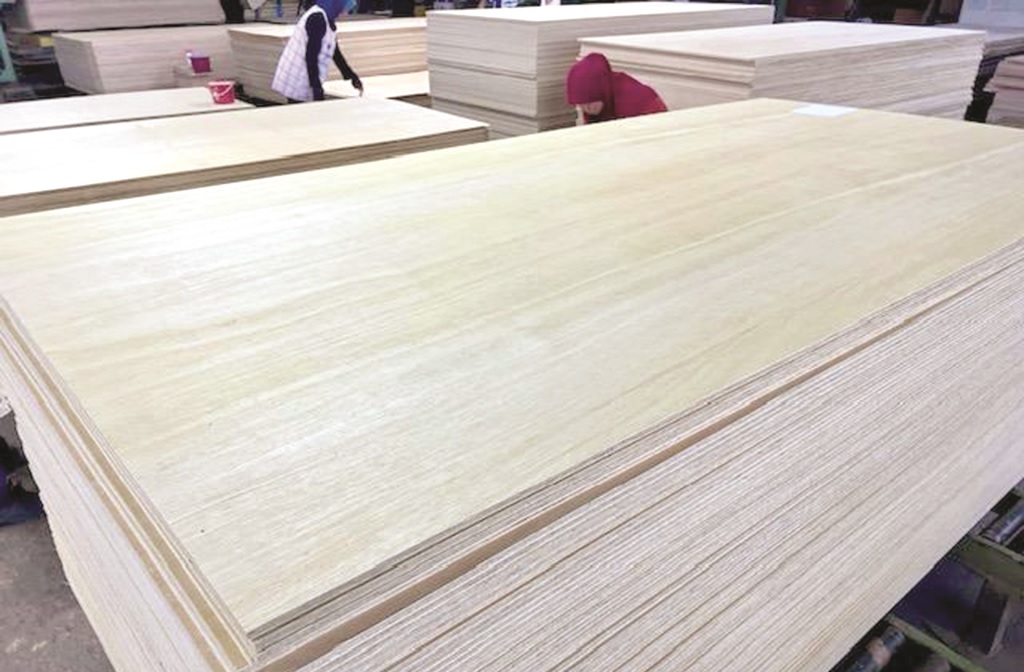

Laran plywood from 100 per cent plantation logs milled in Tawau.

“I have been observing articles on forest plantations but I have not heard anybody coming up with this narrative,” he said.

“As a result, I still don’t think the public has a clear picture of what we are trying to achieve, what our purpose is, which is to replace and substitute logs from tropical forests and save the natural forests.”

Out to make degraded forest productive

“Now that we have shown big yields coming out from our forest plantation, the general public still hold a bad view that salvage logging of degraded areas earmarked for forest plantation development and imagine – oh you are clearing the forests but don’t understand this is a process to save the natural forests,” Rahman said.

“The truth is, we are actually making the degraded forests more productive as intended in 1997, thus, reducing our dependence on the natural forest and logs, hence relieving the pressure on them so that they can regenerate better.

“The yields from my plantation trial harvest last year proves that point and at only five years, we can see the ratio of 1:7.”

“So, let the public understand what is the purpose of forest plantation, it’s the sacrifice of one (degraded forest) to save seven (natural forests).”

Emphasising ‘renewability’

“I also want to emphasise the renewability of forest plantations the rotation of which range from five, eight to 10 years but in the case of natural forests, you wait at least 40 years to come back but with forest plantations, you plant every year on a rotation basis, you have continuity and renewability, you always have the wood and the jobs,” Rahman noted.

Negative thoughts on the time factor has weakened resolve.

Laran-based laminated veneer lumber flooring.

The peeling of Albizia for veneer and plywood in a Tawau mill, from a trial harvest in Jawala. Watching at right is Rahman.

“Some people think the gestation period of eight to 10 years feels so long but I want to say having been in my current concession since 2016, the amount of work, the amount of thinking, the challenges, the amount of management that one has to do, eight years is a short time,” he said.

“You are so busy looking after the project you will not feel eight years is long and now, I have done my harvest of five-year old trees with very promising results and I thought – it was just like yesterday when we started, then you will continue to plant, continue to keep yourself busy, continue with your R&D, your Environmental, Social Governance that you won’t feel it,” he quipped.

Jawala’s problem – concession too small

Of course, there are practical problems, he conceded.

“My problem is that my concession is too small, I think this is very simple logic, given 10 years waiting period for harvesting, I have set aside 31pc for conservation, so I am left with only 6,000ha for planting, so it’s a very simple calculation, in six years, I complete my planting and then you wait 10 years, there is a four-year gap when you reduce or retrench people because there is no planting, after only which you harvest,” Rahman noted.

“My point is forest plantations must have economy of scale, it is about economy of scale, it is a volume game. You cannot say I want to develop forest plantation, give me 2-3000ha, you go and do it.”

Economy of scale lacking

“In our case, the economy of scale is just not there. We do not have a complete rotation, when that happens, we have to retrench people after having developed the skills over six years, then comes the time to retrench, and I can’t say later when I harvest, you come back, there are this kind of challenges.

“So if the State is serious about forest plantations, they must make sure they give out the right size to the right people,” Rahman asserted, quite correctly.

So, what is the right size?

Citing an example, Rahman says if the gestation time is 10 years, one plants 1,000ha per year there’ll be 10,000ha of planted trees in 10 years. On the 11th year, harvest the ones planted 11 years ago, that way, there are no gap years that force shut down and retrenchment.

Belief in R&D to elevate success further

Jawala maintains a tacit belief in R&D, the primary purpose is to forge competitiveness, advance and elevate its current tree planting activities.

“Research and development is very critical to make that number higher – improve the genetics, improve the species so that seven now can replace to 10 or even 20, that is the way forward, we need to disseminate this information and media (such as Daily Express) is part of that ecosystem.”

One way forward is to stay close to researchers in high places.

Professor Kitaya of Kyoto University in Jawala plantation nursery.

“In collaboration with the Universiti of Malaysia Sabah through a five-year MoU signed in 2021, it covers five areas – growth and yield performance of our trees; nursery techniques; high conservation value monitoring; community development and industrial base,” Rahman noted.

“So we have developed a hostel that can accommodate 20 so that we have students and researchers there in my camp, the construction of a dry lab and library is next.

“Collaboration also includes international universities such as Kyoto University and Sweden University of Agricultural Sciences. For a small concession, we have spent a lot of money educating the people. But you know, we believe to remain a forestry player in the future, we have to do this so that they can come and go there to do their Masters up to the PhD level,” he unveiled the depth and vision required.

Confident of the future of forest plantations

“Whether we like it or not wood is here to stay. Imagine a house with no wood inside – you can’t. Carbon is stored in wood for generations even as furniture,” Rahman argued.

“According to Food & Agriculture Organisation, 33 million hectares of forest plantations are needed to supply world wood demand by 2050.

“FMU concessions in Sabah total 1.6 million hectares, with varying sizes, some 60,000ha, some 70,000ha – huge, we are only 11,043-ha but we are very confident of the future of forest plantations,” he said.

“For a small concession, we have put in a lot of effort and as my Chairman (Tan Sri Majid Khan) had told me, the whole idea of collaborating with the UMS is he wants this to be a 100pc Sabahan effort.

“That’s why UMS was selected as the anchor on research, on industrial placement, we want to create more Sabahan foresters but it is very tough as 70pc of UMS Forestry Faculty are female so my next echelon of foresters are females but they are good,” he was quick to soften a mild concern.

“We are trying our best to make it 100pc Sabahans,” Rahman maintained.

“But, of course, we collaborate with Sabah, like the Sarawak Timber Association, as the two Borneo states are in the same boa, so we have to work very closely.”

ADVERTISEMENT